In today’s fashion-driven market, many brands and startups choose custom clothing manufacturing to create unique apparel. However, do you know what truly happens behind the scenes of a production line?

At Lisle Textile, we value transparency and craftsmanship. Therefore, we share a clear step-by-step process from concept to final delivery. As a result, you see how your ideas turn into finished garments.

1. Design & Concept Development

Every great garment starts with an idea. This could be a sketch, digital design, or even a sample. Our team works closely with you to understand your brand’s vision, product goals, target audience, and key features such as:

Fabric type

Fit and sizing

Color preferences

Branding or embellishments

We also assist with mockups to visualize the final product before sampling begins.

2. Pattern Making

Once the design is finalized, our experts create technical patterns — the blueprint of your garment. Patterns ensure accurate sizing, shape, and structure. We offer both standard and custom patterns tailored for men, women, kids, and all size charts including US, UK, and EU measurements.

3. Sampling & Prototyping

Before moving into production, a physical sample is created. This allows you to:

Review construction quality

Approve fabric choice and fit

Request any changes

Photos and videos of the sample are shared for remote approval. In some cases, clients opt for video call reviews to examine every detail in real time.

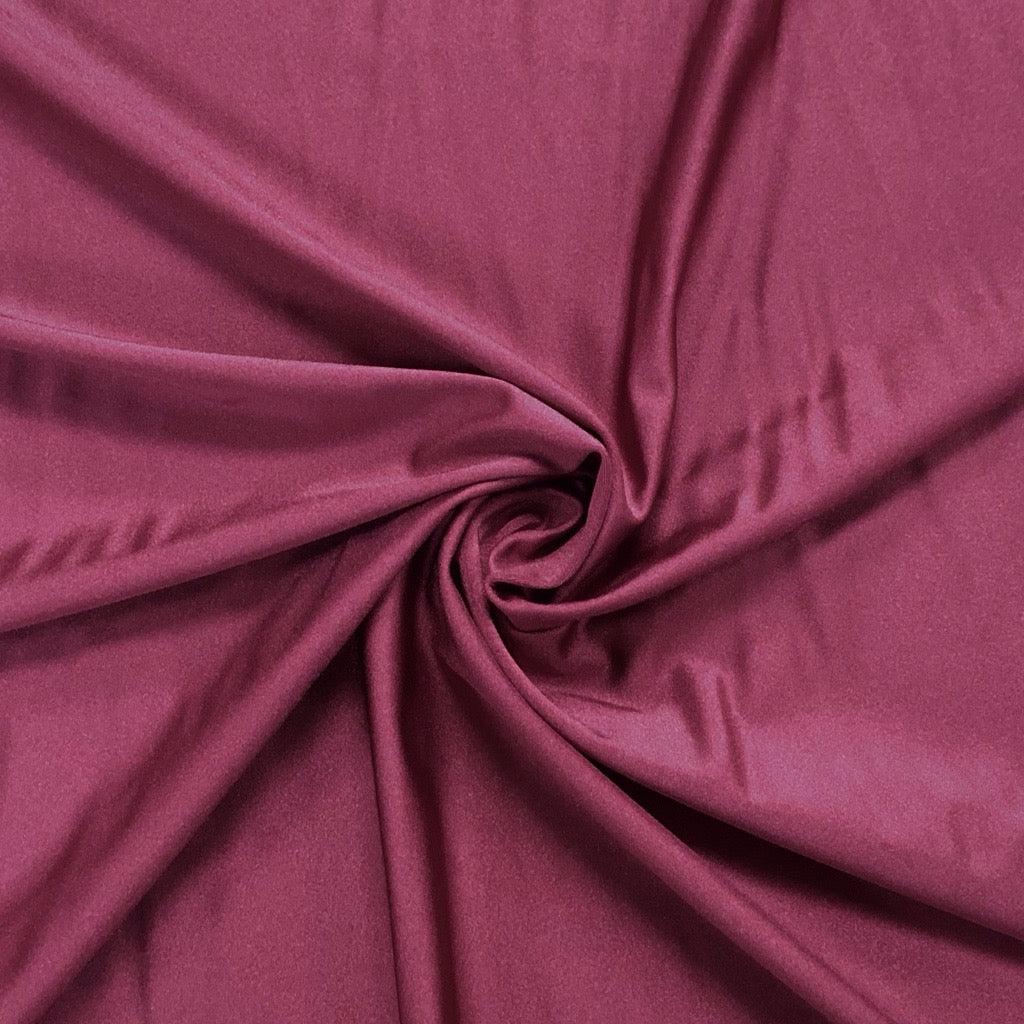

4. Fabric Selection & Color Matching

We offer a wide selection of performance fabrics suitable for streetwear, sportswear, and casualwear — including cotton, polyester, lycra blends, and more.

A vast range of colors is available, with custom color matching on request to align with your brand identity.

5. Cutting

After approval, selected fabric is laid out and precisely cut according to the pattern using manual or laser cutting methods. Accurate cutting is key to perfect fit and efficient stitching.

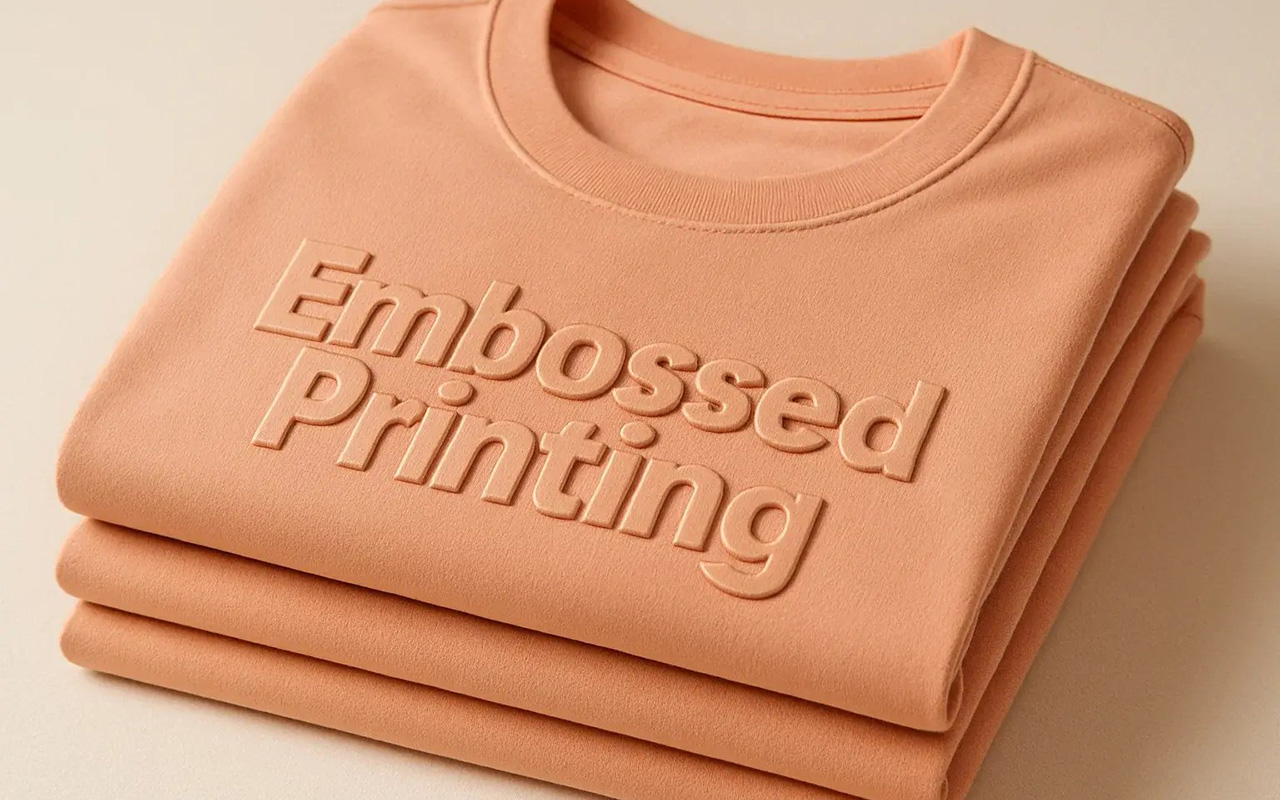

6. Printing & Embroidery

Depending on your design, embellishments are applied using:

Screen Printing

DTG or Sublimation

Embroidery or Chenille Patches

Puff print, 3D print, foil print, etc.

Each technique is selected based on the fabric and style of your garment.

7. Stitching

The cut pieces and embellishments are then taken to our stitching department. Skilled workers assemble the garment using:

Lockstitch

Overlock

Flatlock

Cover stitch machines

Each product is double-checked during stitching to ensure strong seams and clean construction.

8. Private Labeling & Branding

To complete your product, we add custom elements like:

Woven or printed labels

Size tags

Hang tags and packaging inserts

This gives your garment a retail-ready, branded appearance.

9. Final Quality Inspection

Before packing, each item is carefully checked for stitching defects, sizing accuracy, and embellishment quality. Only flawless garments are approved for shipping.

10. Secure Packaging & Shipping

Your garments are then:

Neatly folded and poly-bagged

Packed in durable cartons

Shipped via trusted couriers (DHL, FedEx, UPS) or by air/sea freight

We also offer custom packaging with your logo, artwork, or brand message.

Conclusion

The custom clothing manufacturing process is a detailed journey — one that requires precision, creativity, and craftsmanship at every step. At Lisle Textile, we partner with you from the first sketch to final shipment, ensuring your ideas become reality with professional quality and support.

Have a design in mind? Let’s bring it to life — contact us today to get started with your custom clothing order!

Streetwear

Streetwear

Sportswear

Sportswear

Activewear

Activewear

Jackets

Jackets

Workwear

Workwear

Accessories

Accessories

Gloves

Gloves

Private Labels

Private Labels