Soft warm fabric with rich texture used in coats jackets trims and accessories

Stitching

At Lisle Textile, stitching is the core of our garment manufacturing process. Our production floor is equipped with specialized stitching lines, advanced industrial machines, and skilled operators trained in precision sewing for various fabric types and garment styles. We ensure top-quality results across all garment types, from high-performance sportswear to custom streetwear and fashion apparel.

Stitching Lines & Production Capacity

Total Stitching Lines: 8 Full-Time Production Lines

Daily Production Capacity: Up to 1,200 – 1,800 pieces per day (depending on product complexity)

Monthly Capacity: Approximately 35,000 – 50,000 garments

Shift System: 2 Shifts Per Day (Morning & Evening)

Workforce: 60+ Trained Stitching Operators

Our lines are designed for flexible manufacturing, capable of handling both bulk production and small batch orders efficiently, with consistent quality output.

Stitching Process

Our stitching process is structured to maintain speed, accuracy, and quality control across all garment categories:

- Fabric Panel Preparation: Panels are cut, labeled, and sorted based on size and style.

- Bundling & Distribution: Panels are bundled and assigned to stitching operators by line supervisors.

- Stitching Line Assembly: Stitching is done using appropriate machines (lockstitch, overlock, flatlock, etc.) based on garment design.

- In-Line Quality Check: Stitching is checked during the process for alignment, seam strength, and thread tension.

- Trimming & Thread Cleanup: Excess threads and raw edges are trimmed for a clean and neat finish.

- Reinforcements & Final Stitching: Bar tacks and extra stitching are applied to high-stress areas such as pockets and zippers.

- Final Quality Check: Each garment undergoes a final inspection before moving to the finishing department.

Workmanship

- Skilled Operators: All stitching staff are professionally trained in specific garment categories for precise and consistent results.

- Global Standards: We follow international stitching standards, ensuring strong seams, perfect symmetry, and a clean finish.

- Quality Supervision: Each stitching line is overseen by supervisors and QA personnel to maintain real-time quality control.

- Technical Expertise: Complex and high-performance garments are assigned to senior technicians for optimal fit and construction.

- Craftsmanship Focus: We view stitching as a craft — turning designs into finished garments with care, precision, and reliability.

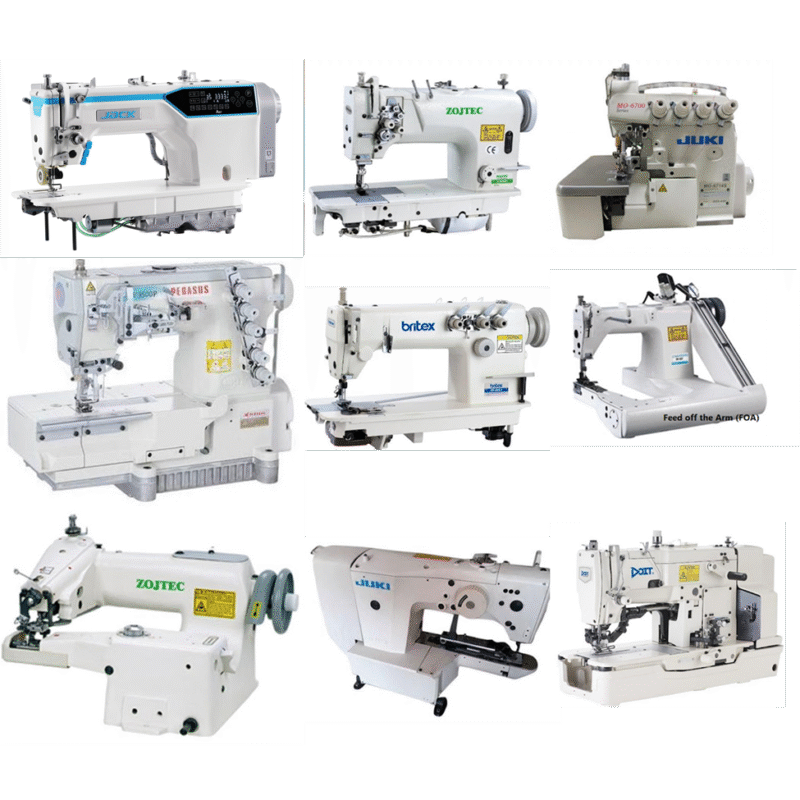

Types of Machines

We use a wide range of advanced industrial machines to ensure the highest quality stitching for every garment type. Our machinery is selected based on the fabric, garment construction, and required finish.

- Lockstitch Machines: For clean and durable straight seams used in most garment types.

- Overlock Machines (Serger): For edge finishing and seam binding, preventing fraying.

- Flatlock Machines: Ideal for sportswear and activewear, offering flat, chafe-free seams.

- Coverstitch Machines: Used for hemming and decorative stitching, especially in knitwear.

- Bar Tack Machines: For reinforcing stress points like pockets, belt loops, and zippers.

- Zigzag Machines: Used in stretchable fabrics and decorative stitching applications.

- Buttonhole & Button-Attach Machines: Ensure uniform and secure button applications.

- Elastic Attaching Machines: Specialized for waistbands, cuffs, and stretch garments.

Our well-maintained machine inventory ensures we can deliver consistent, high-quality stitching across all product lines — from simple tees to complex, multi-panel performance garments.

OUR BESTSELLERS

Nec sem consequat mi gravida augue augue suspendisse condimentum condimentum vestibulum augue mi gravida ugue.

100% Cotton Fleece Sweatpants Joggers Casual Streetwear Supplier

$16.80

Lisle Textile creates 100% cotton fleece sweatpants joggers, ideal for casual wear, streetwear, and loungewear collections. We provide OEM, ODM, and private label services with low MOQs, bulk production, and global shipping. These joggers feature soft fleece fabric and elastic waistbands for comfort and durability. They are perfect for fashion startups, clothing brands, and B2B buyers seeking high-quality, stylish, and versatile activewear products.

100% Cotton French Terry Lightweight 300 GSM Streetwear Sweatsuits and Tracksuits at Wholesale Price

$26.40

Lisle Textile manufactures lightweight 300 GSM streetwear sweatsuits and tracksuits made from 100% cotton French Terry fabric. Fully customizable with your logo, artwork, and private labeling, these sets are perfect for casual wear, loungewear, or streetwear brands. We offer low MOQs and competitive wholesale pricing tailored for startups and small clothing labels.

100% Cotton Jersey Acid Washed T-Shirts Manufacturers Oversized Wash Tees Wholesalers

$9.50

Lisle Textile manufactures and supplies 100% cotton jersey acid washed t-shirts, perfect for brands seeking a unique vintage look. Fully customizable with your logo, design, and private labeling, these wash-effect tees are ideal for startups and small brands. We offer low MOQs and competitive wholesale prices to support your custom clothing line.

100% Cotton Polo Shirts for Men Wholesale Manufacturers Offering Custom Logo Embroidery and Low MOQ

$13.80

Lisle Textile offers 100% cotton polo shirts for men that are comfortable, durable, and stylish. Perfect for sports, casual wear, and corporate uniforms. Brands can add custom logo embroidery, printing, or private labels. We provide low MOQ, bulk orders, and OEM/ODM services. These wholesale polos are ideal for retailers, fashion labels, and promotional apparel suppliers seeking premium-quality cotton shirts at competitive prices.

100% Original Custom Made Cycling Gloves Premium Quality PU Leather Breathable Hand Gear

$15.40

Lisle Textile produces 100% Original Custom Made Cycling Gloves for global wholesale buyers and sportswear brands. These Premium Quality PU Leather gloves offer breathability, durability, and a secure fit. Ideal for cycling, training, and promotional collections, they ensure comfort and performance. OEM and ODM services support logo customization, packaging, and sizing. Low MOQs enable private label buyers to launch exclusive glove lines efficiently.

2PC Set Training Wear Navy Blue Security Uniforms Custom ACU Clothes Breathable Guard Uniform Set

$33.50

Lisle Textile manufactures two-piece navy blue security uniform sets in a breathable ACU design. The fabric offers durability, flexibility, and comfort for training sessions and daily patrol duty. Each set ensures a professional look with functional performance for guards and officers. With OEM, private label, and logo embroidery options, we deliver customized training uniforms for professional security teams.

Streetwear

Streetwear

Sportswear

Sportswear

Activewear

Activewear

Jackets

Jackets

Workwear

Workwear

Accessories

Accessories

Gloves

Gloves

Private Labels

Private Labels